Industrial Automation Benefits of Pneumatic Linear Diaphragm Actuators

Write a comment ...

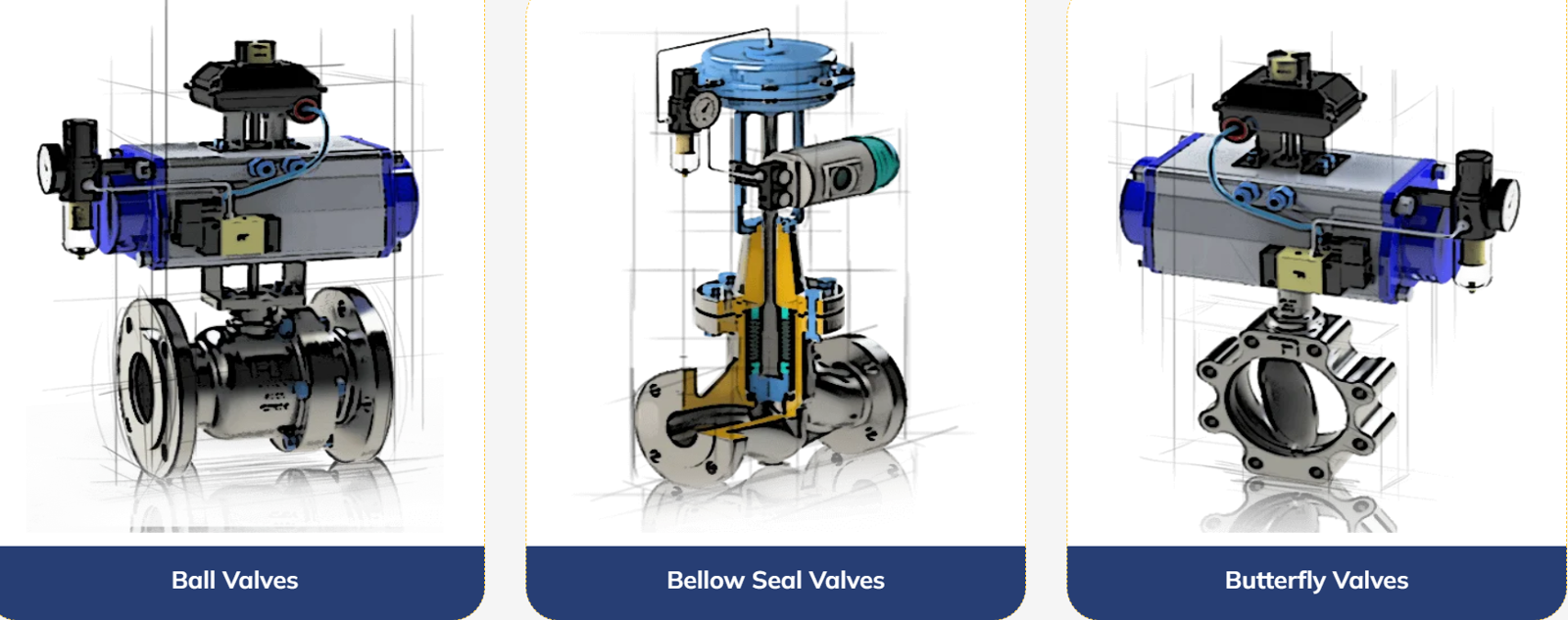

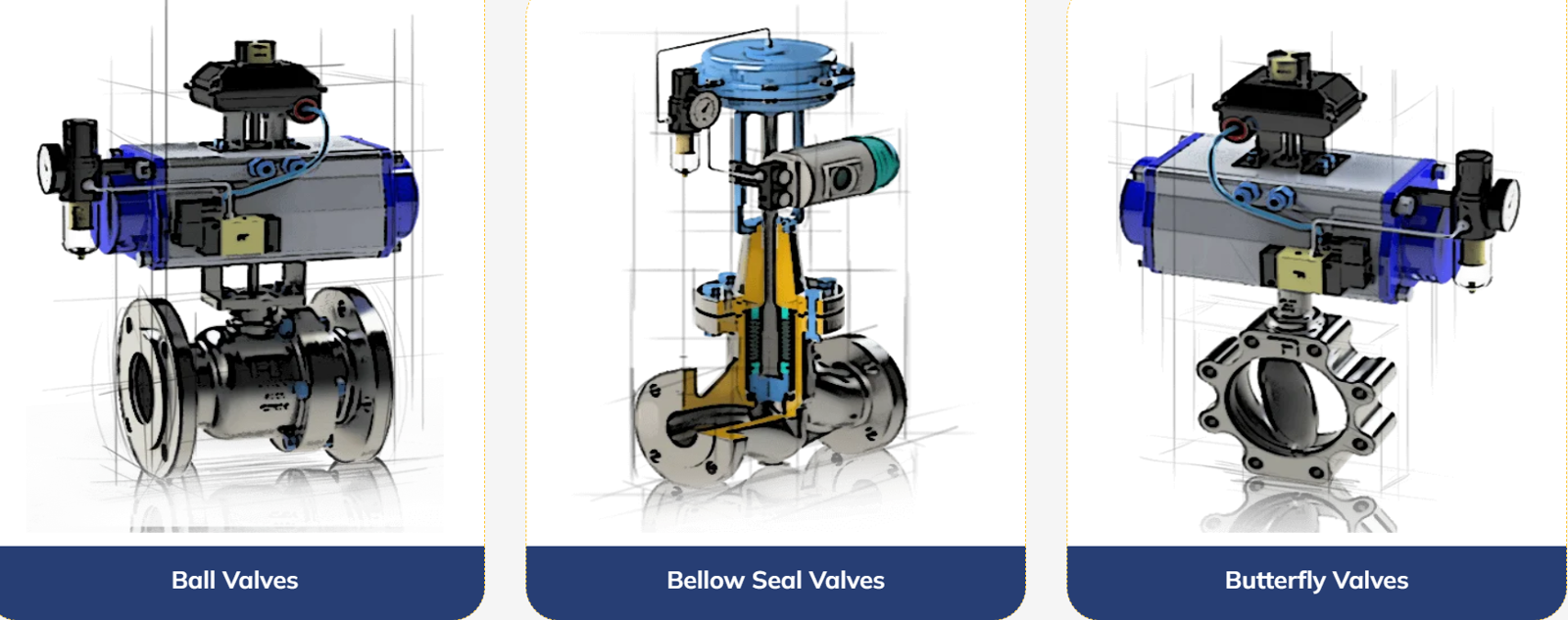

Operational reliability has increasingly become a decisive factor in determining the efficiency and competitiveness of modern industrial facilities. As systems grow more complex and production demands intensify, advanced valve technologies are being adopted to maintain the required flow control, safety, and performance stability. Industrial valves are commonly viewed as basic hardware, but their role has evolved into something far more critical for ensuring smooth operations across multiple sectors such as pharmaceutical, petrochemical, oil and gas, fertilizer, power, food, and process industries.

Double Block and Bleed Valves (DBB) are essential for ensuring leak-proof isolation in high-pressure, high-risk industrial systems. Widely used in oil & gas, chemical, and power sectors, these valves enhance safety, simplify maintenance, and reduce downtime. Discover how DBB valves work, their advantages, key applications, and why Freture Techno Pvt. Ltd. is a trusted manufacturer in Mumbai, India.

In industries where corrosive chemicals, aggressive media, or ultra-pure fluids are transported, choosing the right valve is not just a matter of efficiency—it's a matter of safety, product quality, and system longevity. The PFA Ball Valve emerges as a critical solution for such challenging operations. Engineered with a Perfluoroalkoxy (PFA) polymer lining, these valves offer unparalleled resistance to chemical corrosion, ensuring optimal performance in the most demanding environments.

PFA Ball Valves are designed for highly corrosive and ultra-pure fluid applications, offering exceptional chemical resistance, thermal stability, and leak-free performance. Ideal for the chemical, pharmaceutical, semiconductor, and food industries, these valves ensure reliable flow control in the most demanding environments.

The refining and petrochemical industry plays a pivotal role in global energy and chemical production. Within this demanding sector, extreme operating conditions, hazardous fluids, and continuous operations define the standard environment. To ensure process efficiency and safety, high-performance valves are required. Over time, these valves have evolved into vital components that address persistent industry challenges through innovative engineering and advanced material technologies.

Write a comment ...