In industries where corrosive chemicals, aggressive media, or ultra-pure fluids are transported, choosing the right valve is not just a matter of efficiency—it's a matter of safety, product quality, and system longevity. The PFA Ball Valve emerges as a critical solution for such challenging operations. Engineered with a Perfluoroalkoxy (PFA) polymer lining, these valves offer unparalleled resistance to chemical corrosion, ensuring optimal performance in the most demanding environments.

What Sets a PFA Ball Valve Apart?

PFA ball valves differ from conventional valves primarily due to the PFA lining applied on the internal wetted surfaces. PFA, a thermoplastic fluoropolymer, offers the same chemical resistance as PTFE but provides better mechanical strength, high-temperature tolerance, and greater resistance to permeation.

Technical Highlights:

Temperature Range: -20°C to 200°C

Pressure Rating: Up to 16 bar (depending on size and lining)

Size Availability: From ½" (15NB) to 12" (300NB)

Body Materials: Cast Carbon Steel, Stainless Steel

End Connections: Flanged to ANSI B16.5 or DIN PN10/PN16 standards

Lining Thickness: 3–5 mm of high-purity, anti-static PFA (as per process needs)

These specifications make PFA-lined ball valves highly adaptable for demanding process conditions that would otherwise degrade standard valve materials.

Industrial Applications Where PFA Ball Valves Excel

1. Chemical Processing Plants

One of the most common uses of PFA ball valves is in chemical manufacturing and handling. They are deployed in acid transfer lines, solvent recovery systems, chlorine injection systems, and other corrosive service pipelines. Their resistance to strong acids like hydrochloric, sulfuric, and nitric acids ensures system safety and longevity.

2. Life Sciences and Pharmaceutical Industry

Pharmaceutical manufacturing demands high-purity processing systems. PFA's non-stick surface prevents microbial growth and product adherence, making these valves ideal for systems like Purified Water (PW), Water for Injection (WFI), and Clean-in-Place (CIP) processes.

3. Semiconductor & Electronics Manufacturing

In semiconductor fabrication, ultra-pure chemicals are used for etching and cleaning. PFA-lined ball valves are ideal because they prevent metallic contamination and resist aggressive acids such as hydrofluoric acid, ensuring defect-free chip production.

4. Food & Beverage

PFA-lined valves are FDA-compliant, non-toxic, and odorless. They are used in flavor dosing, CIP systems, and processing of acidic beverages. Their smooth surfaces reduce the risk of contamination and enable easy cleaning.

5. Wastewater and Effluent Treatment

In effluent treatment plants where chemically treated waste is handled, PFA valves resist the harsh nature of waste chemicals, providing durability in neutralization and pH adjustment systems.

Key Benefits of PFA Lined Ball Valves

Unmatched Chemical Resistance: PFA is one of the few materials that can withstand virtually all corrosive chemicals without degradation.

Smooth Internal Surface: Reduces pressure drop, prevents clogging, and supports efficient flow even with viscous or aggressive fluids.

High Purity Compatibility: The inert nature of PFA makes it perfect for cleanroom and high-purity applications.

Fire-Safe and Anti-Static Options: Optional features for hazardous zones and explosive environments.

Long Service Life: The robust lining protects the metal body, reducing maintenance and downtime.

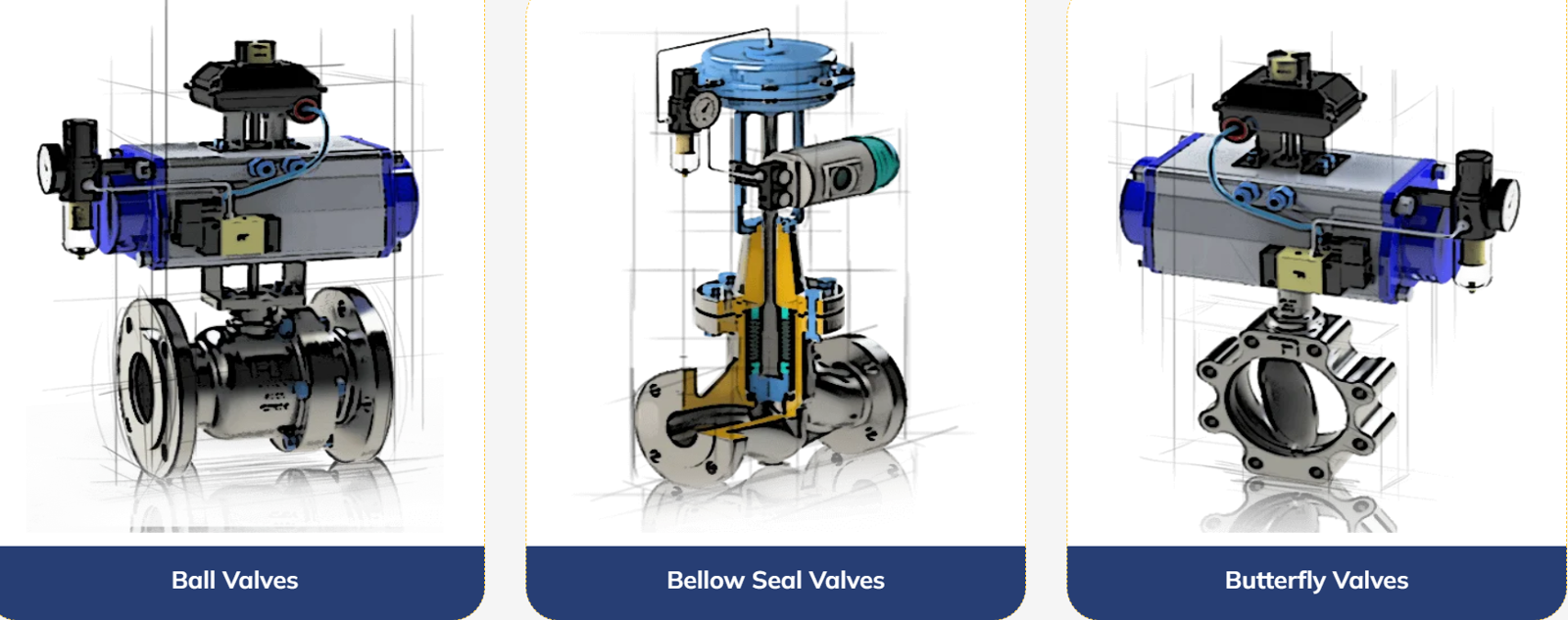

Customizable Actuation: Can be manually operated or equipped with pneumatic or electric actuators for remote and automated control.

Common Challenges Solved by PFA Valves

Corrosion Damage: Prevents costly maintenance and unplanned shutdowns due to pipe corrosion.

Leakage Risk: Provides tight shut-off and minimizes emissions of hazardous substances.

Media Contamination: Ensures purity in food, pharmaceutical, and semiconductor operations by eliminating metal contact.

Frequent Maintenance: The durable lining reduces internal wear and valve sticking, ensuring longer cycles between maintenance intervals.

Conclusion

PFA Ball Valves are more than just flow control devices—they are protection mechanisms for your critical process infrastructure. From handling dangerous acids to ensuring ultra-pure media transfer, PFA-lined valves deliver safety, compliance, and operational excellence across a wide range of sectors.

For organizations seeking precision-engineered PFA Ball Valves, Freture Techno Pvt. Ltd., based in Mumbai, India, offers a trusted solution. As a leading valve manufacturer, Freture Techno brings together robust engineering, global standards, and industry-specific customization to support safe and efficient fluid handling systems.

Write a comment ...