Operational reliability has increasingly become a decisive factor in determining the efficiency and competitiveness of modern industrial facilities. As systems grow more complex and production demands intensify, advanced valve technologies are being adopted to maintain the required flow control, safety, and performance stability. Industrial valves are commonly viewed as basic hardware, but their role has evolved into something far more critical for ensuring smooth operations across multiple sectors such as pharmaceutical, petrochemical, oil and gas, fertilizer, power, food, and process industries.

In many plants, production stability is directly dependent on how effectively valves regulate flow, pressure, and direction of critical fluids or gases. High-performance valves are engineered to function under severe service conditions, including corrosive chemicals, volatile hydrocarbons, high-pressure steam, slurries, and temperature extremes. When a valve fails to perform its intended function, the effects cascade quickly: product contamination occurs, energy losses increase, pressures fluctuate, and safety margins narrow. This makes valve technology central to maintaining operational reliability.

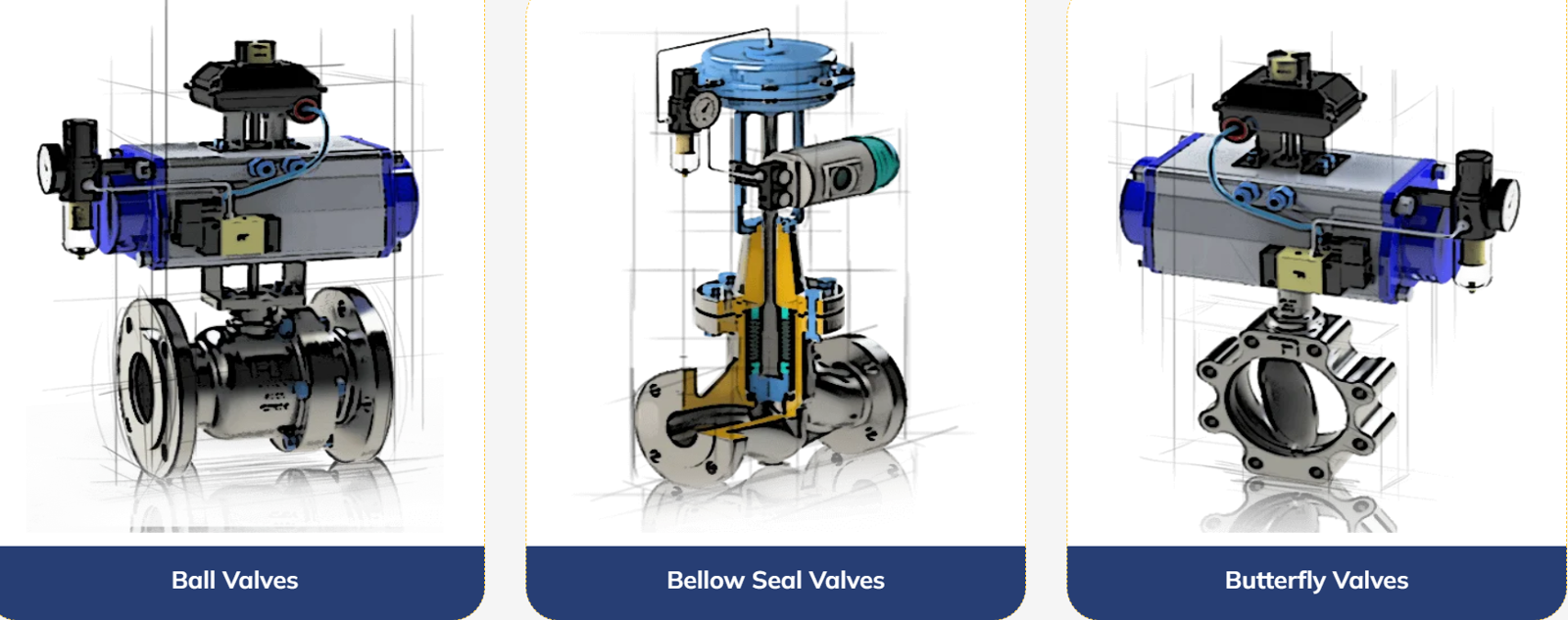

Modern valve engineering has shifted toward precision manufacturing, advanced sealing technologies, and smart instrumentation. Zero-emission designs, bellow seal technologies, and high-integrity seat materials ensure long-term reliability even in high-cycling or high-torque applications. Industries such as pharmaceutical manufacturing, which depend on clean-in-place (CIP) and sterile flow systems, benefit from hygienic valves equipped with polished surfaces and contamination-free shutoff mechanisms.

Digitalization has also played a significant role in improving valve performance. Smart positioners, online diagnostics, and predictive maintenance platforms allow engineers to continuously monitor valve health. Parameters such as stem friction, leakage rates, vibration levels, and actuator load are tracked in real time. This data-driven approach enables early detection of abnormalities, reducing unexpected downtime and enabling more efficient maintenance planning.

Energy optimization is another significant advantage of modern valve technologies. Poorly performing valves introduce throttling losses, affect pump load, and contribute to unnecessary energy consumption. By contrast, well-selected and well-maintained valves help maintain stable pressure levels, minimize flow disturbances, and reduce overall operational costs. In sectors such as power generation and fertilizer production, where large-scale fluid movement is common, this improvement in energy efficiency translates directly into measurable financial gains.

Safety performance is strengthened when valves operate reliably. In oil and gas and petrochemical environments, relief valves, isolation valves, and emergency shutdown valves (ESDV) form the first line of protection against hazardous releases. High-integrity valves designed for fire-safe service or corrosive media ensure that risk is kept under control. Compliance with international standards such as API, ASME, EN, and ISO further guarantees that valves meet safety-critical requirements for global operations.

Long-term lifecycle management of valves offers additional value. Predictive maintenance strategies, combined with high-quality valve construction, reduce the frequency of repairs. Plants can extend intervals between overhauls and achieve smoother production cycles. Spare parts availability, material compatibility, and ease of servicing also influence the total lifecycle cost. When valve performance remains consistent over extended periods, operational reliability improves, and plants can meet their production targets more effectively.

In summary, operational reliability in modern plants is increasingly shaped by advancements in industrial valve technologies. As industries continue to modernize, the importance of selecting the right valve, deploying smart monitoring tools, and maintaining rigorous maintenance practices becomes indispensable. High-performance valves ensure stable flow control, reduce downtime risks, enhance safety, and ultimately contribute to a more predictable and efficient production environment.

Write a comment ...