The refining and petrochemical industry plays a pivotal role in global energy and chemical production. Within this demanding sector, extreme operating conditions, hazardous fluids, and continuous operations define the standard environment. To ensure process efficiency and safety, high-performance valves are required. Over time, these valves have evolved into vital components that address persistent industry challenges through innovative engineering and advanced material technologies.

Challenges Faced by the Refining and Petrochemical Industry

Numerous challenges are encountered in refining and petrochemical operations. Chief among them is the management of high temperatures and pressures. Units such as catalytic crackers, distillation columns, and reactors operate under extreme thermal and pressure conditions, where even minor failures can result in catastrophic consequences. In such environments, conventional valves are often prone to mechanical fatigue and thermal expansion-related leakage.

Additionally, the handling of aggressive and corrosive chemicals presents significant risks. Substances such as hydrogen sulfide, acids, and volatile hydrocarbons can deteriorate conventional valve internals, leading to premature failures. Maintenance downtime caused by valve failures affects production schedules and increases operational costs.

Moreover, the industry's regulatory landscape has grown increasingly stringent. Emissions control and safety standards must be adhered to under agencies such as OSHA, EPA, and API. Valves that emit fugitive gases or allow product leakage can lead to environmental penalties and safety hazards. As such, reliability and leak-tight performance have become non-negotiable.

Valve Technologies That Address Industry Pain Points

To mitigate these challenges, specialized valve technologies have been developed. High-pressure valves have been designed to withstand elevated system pressures without compromising structural integrity. The use of corrosion-resistant alloys such as Hastelloy, Monel, and Inconel extends valve life in chemically aggressive environments.

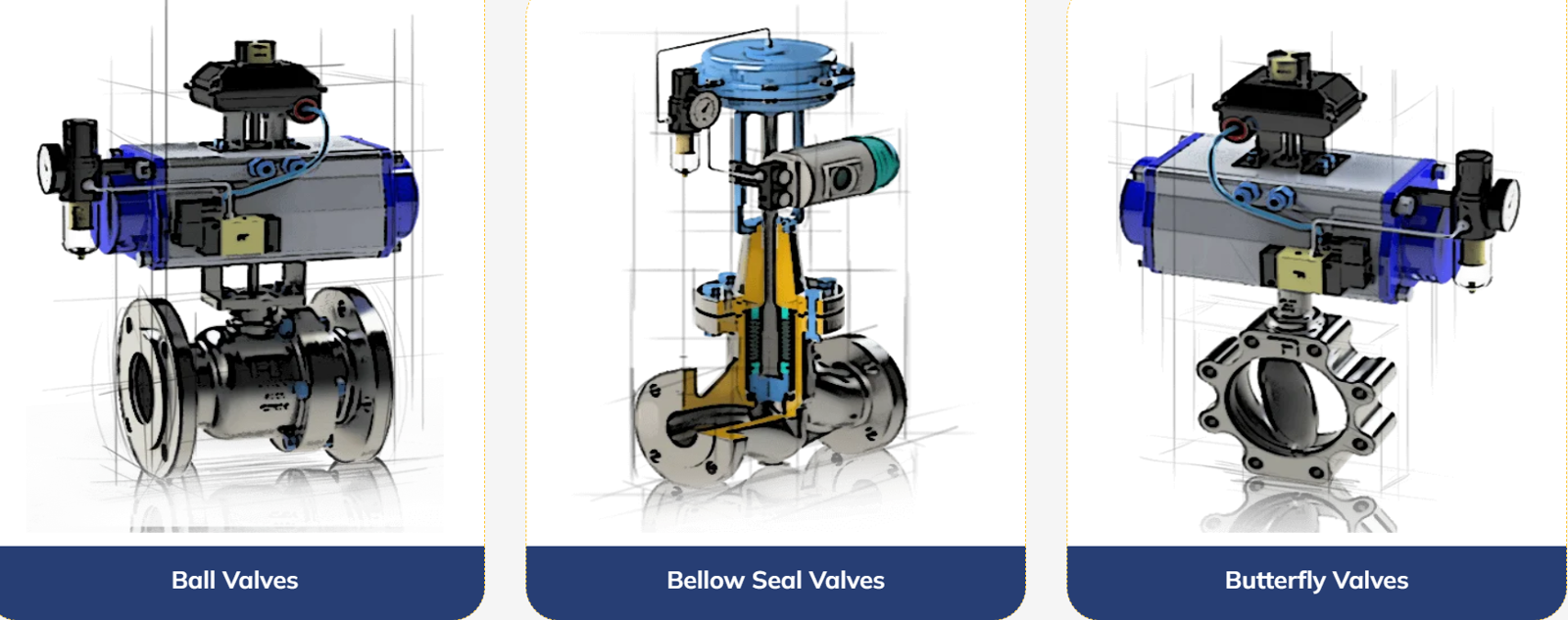

For thermal resilience, valves with reinforced seals and high-temperature packing materials are deployed. Bellow sealed valves are often used in critical applications to ensure zero emissions and eliminate stem leakage. These valves feature a flexible metallic bellows that acts as a seal, preventing toxic or flammable substances from escaping.

Ball valves with zero-leakage capabilities have also become widely utilized in refining and petrochemical operations. These valves are engineered to provide bubble-tight shutoff, thereby minimizing product loss and environmental impact. Globe and gate valves, equipped with advanced seating designs and fire-safe construction, are used in process-critical systems.

Role of Automation and Smart Valve Monitoring

Automation has been integrated into valve systems to improve control and reduce manual intervention. Automated valves equipped with electric or pneumatic actuators are used to regulate flow parameters with precision. This level of control has enhanced process efficiency and reduced human error.

Moreover, the implementation of smart valve monitoring systems has transformed predictive maintenance. Sensors and digital diagnostics are now embedded in valve systems to monitor performance metrics such as vibration, temperature, and pressure in real time. As a result, potential failures are identified before they escalate, leading to improved safety and minimized unplanned shutdowns.

Innovations in Valve Design and Compliance

Compliance with industry standards such as API 600, API 6D, and ISO 15848 has been a driving force in valve innovation. Fire-safe valve designs have been introduced to maintain structural integrity during fire exposure. Fugitive emission control features, including low-emission packing and dual stem seals, are now standard in high-specification valves.

Valves are also being designed with modular components, allowing for easier maintenance and part replacement without full system shutdown. This modularity, combined with standardized face-to-face dimensions and end connections, ensures compatibility across different systems and manufacturers.

Conclusion

Within the Refining and Petrochemical industry valves have transitioned from simple flow control devices to critical components that safeguard operations, enhance productivity, and ensure regulatory compliance. By addressing key challenges such as extreme conditions, corrosive media, emissions control, and downtime, modern valves have become indispensable in ensuring efficient and safe refinery and petrochemical operations.

Partnering with reliable petrochemical valve manufacturers who offer advanced, compliant, and durable solutions remains essential for operational success in this high-stakes industry.

Write a comment ...